Last Friday, the European Commission’s Nitrates Committee voted to amend Annex III of the Nitrates Directive to allow certain processed manure‑derived products (RENURE) to be used above the existing limit for livestock manure. The European Commission had proposed to reclassify RENURE as an inorganic fertiliser with a new limitation of 80 kg N/ha/year.

The Commission's RENURE proposal will now be shared with the European Parliament and the Council for a three-month scrutiny period. If there are no objections from the European Parliament and the Council, the Commission will be able to adopt this amendment to the Nitrates Directive. The final text should be published in the Official journal in Q1 2026.

What is RENURE?

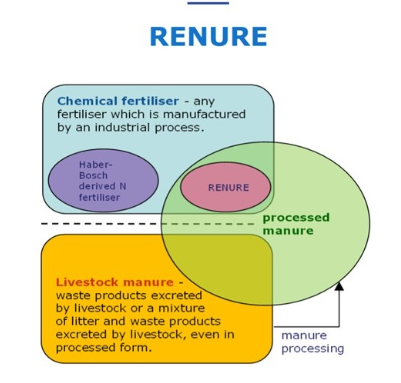

RENURE or REcovered Nitrogen from manURE is a fertiliser obtained from the processing of livestock manure that meet specific conditions. It is therefore undistinguishable from chemical fertilisers and generated by an on farm-process. RENURE fertilisers can be obtained through different systems and techniques. Current techniques, all based on the extraction of NH3 from the gasification of livestock manure via stripping/scrubbing. Towards the future, the technique of membrane filtration also offers potential. These are techniques that can be applied according to economic considerations at the level of individual family cattle farms from a farm size of 100 to 120 dairy cows.

Farm visit in Flanders

I visited a farm in Flanders in June 2025, alongside the UK Unions officeholders, where there was a pocket digester where the slurry is first fermented for methane production as a basis for their own electricity and heat production. The digested slurry is then separated into a thick fraction which is used as box bedding for their cows, and thin fraction which is stimulated in a reactor to produce NH3, which is washed out of the extracted air (stripping/scrubbing) with sulphuric acid or nitric acid, giving NH4SO4 or NH4NO3 as the end product.

End products of RENURE

After separation of manure and washing the manure air, three end products are condensed from slurry:

- Thick fraction (high in P, high in organic C): use as box bedding for cows or use as organic matter application and P fertiliser in fruit growing, viticulture, ...

- Thin fraction digestate (low in N, low in P, high in K): valuable fertiliser for potassium-loving crops such as grassland, potatoes, carrots, sugar beet

- RENURE salts (NH4SO4 or NH4NO3): 8 or 15% N) : suitable for both grassland, arable and open-air vegetable crops (applicable as liquid fertiliser)

Benefits of RENURE products

There are several advantages associated with the production and use of RENURE products:

- Circular: the nitrogen from manure is better utilised and a larger part of the manure can remain in the production region. There is less transport of manure over long distances.

- Precision fertilisation: RENURE products better meet crop demand (like fertiliser) leading to better nutrient utilisation and less leaching of unused nutrients

- RENURE fertilisers are free of pathogens and antibiotics

- Lower NH3 emissions: in combination with NH3 reducing techniques at stable level, there are substantially lower ammonia losses in the stable and when applying manure to the land (up to 66% NH3 reduction)

- Less reliance on artificial fertilisers:

- Through better nitrogen utilisation and precision fertilisation, less fertiliser is needed. This reduces the use of fossil fuels (natural gas) and leads to greater independence from Russia (currently EU countries are between 30 and 40% dependent on Russia for N fertilisers and between 50 and 60% dependent on Russia or P fertilisers)

- Lower CO2 footprint through reduced fertiliser use. Fertiliser production releases 8500 kg CO2eq per tonne of active nitrogen that can be avoided

- Combination with own energy generation

- The RENURE techniques can be combined with a mono-digester or pocket digester at farm level. Here, the slurry is first fermented for methane production as a basis for own green electricity production and heat.

- The digested slurry can then be separated into a thick and thin fraction to then further process the thin fraction. This creates a total farm-level package with energy generation and RENURE production.